We can produce wide range of steel flanges with outstanding quality.

MANUFACTURING STEEL PIPE FLANGES SINCE 2000

Shandong ZhongNuo Heavy Industry Co., Ltd. is one of the best manufacturers of forged Flanges in China. We manufacture various type of flanges that meet customers’ service and quality demands according to international standards, such as ASME/ ANSI B16.5 flanges, ASME/ ANSI B16.47 flanges, JIS flanges, DIN flanges, EN 1092-1 flanges, AWWA flanges, BS 4504 flanges, SABS/ ASNA 1123 flanges, etc., and we can also manufacture special flanges according to customers’ draws.

Все още не намирате това, което търсите?

Свържете се с нашите консултанти за повече налични продукти.

We offer direct factory price and guarantee the high quality.

We have our own efficient and feasible quality management system to ensure quality control in every detail, from supply chain audit to bulk production to shipment.

Our order system makes it easy for us to keep track of the progress of each order, and ensure that all orders are shipped within the deadline.

Excellent after-sales service is an important factor in maintaining sustainable cooperation. We provide our customers with worry-free after-sales service to ensure that the problems you encounter are solved within 1-3 working days.

We mainly manufacture carbon steel and stainless steel flanges, commonly used materials are as follows:

Carbon steel flanges: A105, SS400, SF440 RST37.2, S235JRG2, P250GH, C22.8, etc.

Stainless Steel flanges: ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

The manufacturing of forged flanges can be divided into 8 processes: Forging-Machining-Drilling-Deburring-Marking-Surface Treatment-Inspection-Packing. Each process must be designed to ensure the highest product qualification rate.

Get A QuoteA pipe flange is a piping component that connects to a piping system by using bolts and gaskets. A gasket is added between two flanges and then fastened with bolts. The most common types of flanges are weld neck flanges, slip on flanges, plate flanges, blind flanges, socket weld flanges, threaded flanges, lap joint flanges and RTJ flanges. Pipe flanges are usually made of carbon steel or stainless steel, through series of forging process, so it is also known as forged flange.

Forged flanges are widely used in petrochemical, chemical, nuclear industry, mining, oil and gas, construction, waterworks, etc. The dimensions of forged flanges are classified from 1/2″ to 60″, and pressure classified from 150# to 2500# or from PN6 to PN100.

Weld Neck flanges

Този тип фланец е най -широко използваният тип в тръбопроводите на процеса, той е проектиран да бъде свързан с връзка за заваряване на дупе към тръбата. Фланците на заваръчната шия се използват при приложения с високо налягане и температура.

Плъзгащи се фланци

Плъзгащият фланец е свързващ пръстен, който се плъзга над края на тръбата. Фланецът е в състояние да се плъзга напред -назад по тръбата за лесно позициониране, а вътрешността и външната страна на тръбата трябва да бъдат заварени към приплъзването на фланеца. Плъзгането на фланец е подходящо за приложения с ниско налягане и температура.

Blind Flange

Сляпото фланец е солиден фланец с дупка на болта. Използва се за затваряне на края на тръбата или оборудването. Сляпата тръбна фланец се използва и като капак на шахтата в съда.

Plate Flange

Плачният фланец е плосък, пръстен с отвор за болт. Този тип фланец е заварен до края на тръба и се закрепва към друга тръба. Два плочи фланци могат да бъдат закрепени заедно с уплътнение между тях. Фланците на плочите са подходящи за приложения с ниско налягане и температура.

Threaded Flange

Фланците с резба/винт са предназначени за свързване на фланци и тръби посредством резби. Това означава, че мъжките резби на тръбата се завинтват в женските резби на фланеца, за да се завърши свързването на тръбопроводния процес. Фланците с резба са подходящи за приложения с ниско налягане и температура.

Заварени фланци с гнездо

Flange Flange за заваряване (SW) е проектиран за малък размер и тръбопровод с високо налягане, той има край на гнездото в отвора на фланец за тръба, за да го постави и да направи филе заваряване.

Фланец на скута

Фланецът за препокриване (LJF фланец) се нарича още свободен фланец, той има два компонента, край на щифта и хлабав опорен фланец. Краят на щифта е челно заварен към тръбата, а опорните фланци се движат свободно по тръбата. Фланецът LJF се използва особено за често демонтиране или трудни за регулиране тръбни връзки.

Ring Type Joint Flange (RTJ flange)

Фланец тип пръстен (RTJ фланец) е жлеб, изрязан в уплътняващата повърхност на фланеца. По-мекото уплътнение на стоманен пръстен се поставя в жлеба, което създава уплътнение от метал до метал, когато уплътнението е в компресия. Този тип фланец е предназначен за приложения за тръбопроводи с високо налягане и висока температура.

Zhongnuo manufactures a wide variety of steel pipe flanges meeting following standards:

ASME/ANSI B16.5 flange

ANSI B16.47 flange

BS 4504 flange

DIN flange

EN 1092-1 flange

SANS/SABS 1123 flange

ASA flange

JIS flange

AWWA flange

GOST flange

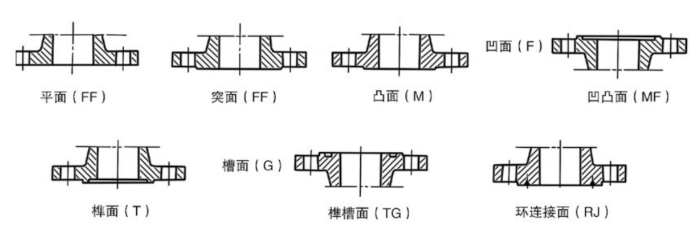

Different standards and applications require for different type of sealing face on the flange. The sealing surface of the flange is usually machined with a certain roughness and place the gasket for better sealing.

The most used types are:

Raised Face (RF)

Flat Face (FF)

Ring-Type Joint (RTJ)

Male-and-Female (M&F)

Tongue-and-Groove (T&G)

For easy identification, the flange is marked with the corresponding parameters on the side, including brand name, size, pressure class, material, international standard, heat number, etc. We can also stamp according to customers special requirements.

The serrated flange surface means that concentric circular grooves or continuous spiral grooves are machined on the flange sealing surface. The main function is to increase the friction between the flange and the gasket to make a tighter connection between the pipe and the flange.

Usually, we machine flange serration with the groove width 0.8mm and groove depth 0.2-0.25mm, however we can also machine the serration on flange according to customers’ requirements.

We are a factory, and we offer factory direct prices with excellent quality and professional service.

Of course, you can come in person or hire a third-party organization to inspect our factory.

To ensure the integrity and safety of product packaging, products are packed in plastic film or export plywood boxes.

China has a much better industry chain. There may be manufacturers of steel flange in India, Vietnam and Malaysia, but Zhongnuo can guarantee that our prices can be on par with theirs and our quality, service far exceeds your expectations.

We can manufacture flanges according to your drawings, based on our many years of experience in the industry.

We offer you a 1-3 year warranty on our high-quality flanges.

We have been certified by TUV ISO9001, PED/AD2000, KR,KS certification bodies.

We offer EXW, FOB, CFR, CIF delivery terms.

You can come to inspect the goods in person, or you can hire a third-party inspector or agency to inspect the goods. In addition, all of our products are inspected to be qualified and issued test certificates before shipment.

Zhongnuo е добре известен производител на фланци, изковки и стоманени тръби от въглеродна стомана с над 20-годишен опит. Нашите силни възможности и опит ни позволяват да отговорим на комплексните нужди на нашите клиенти по целия свят...

Авторско право 2017 – 2022 Zhongnuo | Всички права запазени