Reliable Supplier of Steel Flange

Our Main Product

ZHONGNUO Is A Leading Forged Flange Manufacturer from China

Over 20 years ZHONGNUO focus on carbon steel flange manufacturing

Established in 2000

Employees: 220

Certificates: TUV ISO9001, PED/AD2000, KS and KR

Area: 27,000 sqm

Capital of the company: USD 2.500.000,00

Monthly output: 1800 tons

Shandong Zhongnuo Heavy Industry Co., Ltd. is a leading manufacturer of steel flanges in Zhangqiu, China. We can produce all types of flanges according to ANSI B16.5, EN1092-1, DIN, BS, UNI, SANS1123, JIS, AS2129, AS4087, AWWA, ISO, and GOST standards. 20 years of experience, excellent quality, and competitive price bring us stable and trusted customers all over the world.

In Zhongnuo, we believe in “survive by quality, develop by innovation”. Our company is certified by TUV ISO 9001, PED/AD 2000, KS, and KR. We also developed our own quality management system, aiming to provide our customers with stable and premium products.

Why Choose Us

We Are Leader in Flange Market

With more than 20 years of experience working with flange stockiest, distributors, traders and engineering in large and small, we can manufacture and customize all types of flanges according to international standards.

Quality Control

We have been committed to quality assurance and this has allowed us to stay in the market for so many years. Our well-trained QA and QC team ensure that our products meet the highest standards.

Real Factory

As a professional flange manufacturer, Zhongnuo has advanced production line and lab. High quality, fast delivery, and high cost -effective, we can meet the manufacturing and customization of all flange types.

High Responsibility

We always look for long-term relationships with our clients and taking their needs seriously. Many of our clients worked with us for many years and now they still choose us. We always aim for a sustainable business model that benefits both sides.

Warranty Service

We understand that when you purchase something, you expect it to work perfectly. But sometimes things don't go as planned. With our efficient after-sales procedures, you can get quick solutions within 1-3 business days.

Testimonial

Client Love

Contact

Submit A Request

Want to learn more about us? you can contact us immediately to ask a question or request a quick quote for your business.

Our Gallery

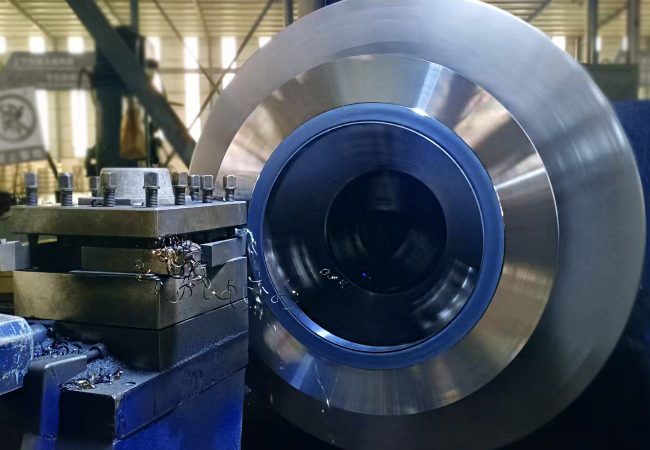

How the carbon steel flanges manufactured

1. Forging

The red-hot billet is formed by forging. The flange blank will obtain stable mechanical properties when through heat treated process.

2. Machining

Removes the oxide layer on the flange surface, polishing process makes the flange appears smooth and bright surface.

3. Drilling

Drilling according to the hole diameter and hole number.

4. Deburring

Removing sharp edges.

5. Stamping

Stamping according to the flange size, Pressure value, international standard, material, flange type, heat number, etc.

6. Surface treatment

The most popular surface treatment include anti-rust oil, paint, hot-dip galvanizing, and electro-galvanizing.

7. Inspection

Quality inspection before delivery, every batch of shipment will accompany with test report.

8. Packing

The packaging should be suitable for sea and land transportation. The packaging should be convenient for customers to tally and check the goods.

Our News

Latest News & Articles

5 Things You Need to Know About Carbon Steel Flanges

When it comes to industrial applications that require strength, durability, and reliability, carbon steel flanges are a popular choice. These essential components play a crucial role in connecting pipes and valves, ensuring the safe and efficient flow of fluids in various industries. In this comprehensive guide, we will explore the key aspects of carbon steel […]

Pipe Flange Basics: Functions, Types, and Uses

Pipe flanges are used in a variety of industrial applications, such as oil and gas, water, and chemical processing. They are used to join two or more pipes together or to connect a pipe to a valve or other piece of equipment. Flanges come in a variety of shapes and sizes, with different materials and […]

Weld Neck Flange

What is a weld neck flange? A weld neck flange is a type of pipe flange commonly used in piping systems. It is designed to connect two pipes or other components together by welding. Weld neck flanges are used in a variety of applications, including water and steam systems, oil and gas pipelines, […]